Custom Part & Mould Design

Get precision-designed parts and moulds that drive your product’s success. PenPlast offers a full-service design experience to help you get production-ready parts that meet your exact requirements—quickly and cost-effectively.

Avoid costly mistakes and delays with expertly designed parts and moulds.

Custom part and injection moulding design requires precision, insight, and careful planning. Without the right expertise, mistakes in design can lead to costly delays, rework, and compromised quality.

PenPlast’s design team partners with you to eliminate these risks, ensuring your mould and part are expertly designed the right way from the start.

You’ll benefit from a streamlined process that combines deep industry expertise, 3D modeling, and hands-on guidance—whether you’re creating a new product or improving an existing design. The result? A faster path to market with reduced risk and built-in quality.

Get a design partner who ensures your moulds are built for success from day one

Design Consultation

Refine every design element, from material flow to cooling, for a part that performs seamlessly. We’ll help you avoid common injection moulding design pitfalls, ensuring your mould is durable, efficient, and tailored to your needs.

New & Existing Parts

Whether developing a new part or auditing existing designs, we provide hands-on guidance to improve manufacturability and reduce costs—without compromising quality.

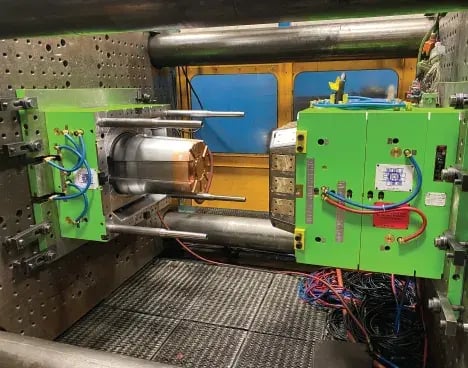

Error-Free Mould Creation

In-House Tooling & Production Support

Proactive Quality Assurance

Comprehensive Mould Care & Maintenance

Your all-in-one partner for injection moulding design

Simplify your supply chain with a single partner handling every step of your injection moulding process.

- Save time

- Reduce costs

- Cut lead times

- Boost efficiency

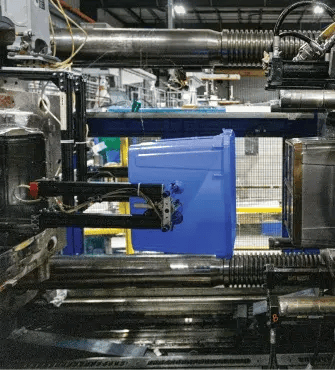

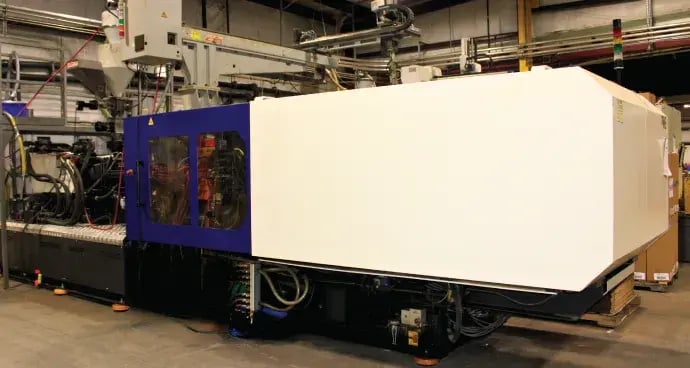

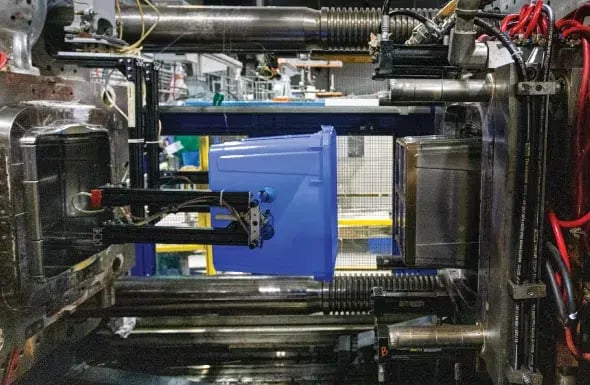

Injection Moulding Capabilities