Onboarding & Consulting

Save time. Cut costs. Improve efficiency.

From day one.

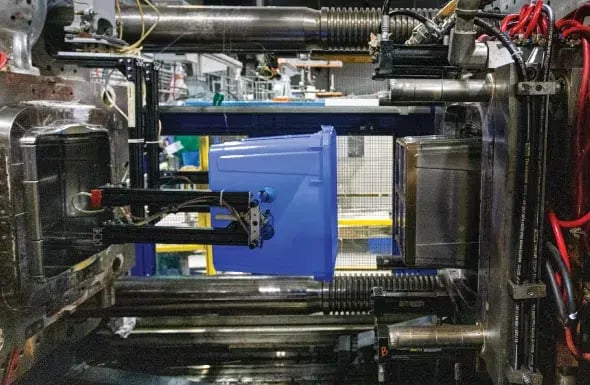

Switching injection moulding suppliers can feel risky, especially when you lack full specs on your existing moulds. Without accurate data, you risk pricing surprises, wasted time, and potential quality issues.

PenPlast’s onboarding service takes the guesswork out of the transition. Our team goes on-site to inspect and record all necessary data—from cavity numbers to dimensions—so you get clear, reliable pricing and confidence in compatibility. We’ll also help you establish a quality assurance plan tailored to your needs, ensuring production meets your standards from the start.

Enjoy a smooth, stress-free onboarding experience.

On-Site Assessment

Our team visits your facility to thoroughly understand your moulds and production setup, capturing every detail to ensure a smooth transition.

Data Analysis

With all key data in hand, we evaluate your moulds, parts, and materials to provide customized recommendations that align with your specific requirements.

Pricing Proposal

Receive a transparent, custom pricing plan based on your needs. We’re here to answer any questions and make adjustments as necessary.

Quality Assurance

Together, we develop a quality assurance plan that meets your standards, aligning our processes with your expectations.

Start Production

With everything prepared, you’re ready to move into production with complete confidence in our partnership.

Your all-in-one partner for injection moulding

Simplify your supply chain with a single partner handling every step of your injection moulding process.

- Save time

- Reduce costs

- Cut lead times

- Boost efficiency