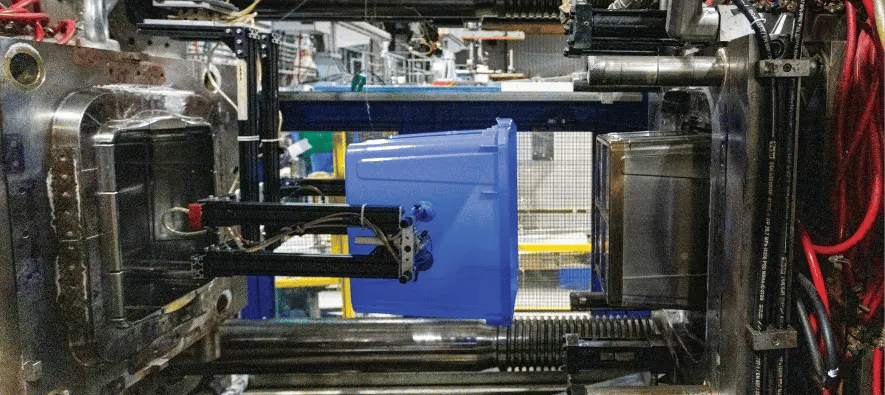

Custom Injection Moulding

A custom injection moulding process that puts you in control. PenPlast takes the complexity out of manufacturing with complete, end-to-end services—from design and production to warehousing and delivery—all in one place.

Delivered on time. Made to spec. From a single source.

When managing high-stakes production, juggling multiple suppliers can create delays, increase costs, and make it harder to meet your goals. With PenPlast, you can simplify the process and work confidently with a single partner who handles every detail.

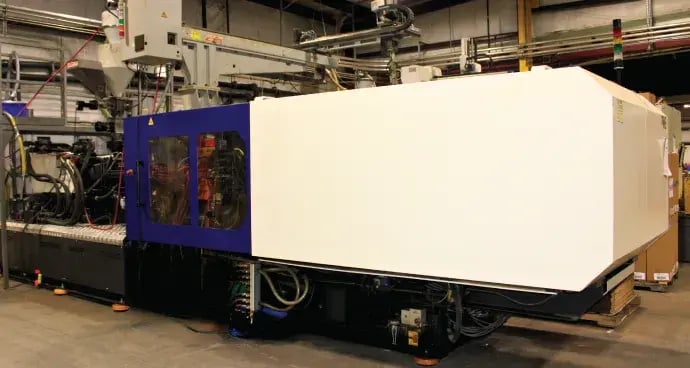

You gain access to machine versatility that meets the demands of any project size, backed by strategic cross-border logistics to support faster, cost-effective delivery. With total transparency and continuous communication, you’ll stay in control at every stage.

Choosing PenPlast can save you time and money without compromising quality.

A cost-effective, eco-friendly choice.

End-to-End Project Management

You’ll save time and reduce headaches with our all-in-one approach to custom injection moulding, which takes care of each step from prototyping to packaging—all under one roof.

Flexible, Around-the-Clock Production

With 24-hour operations and cross-border logistics, your parts are ready when you need them, helping you keep deadlines tight and shipping efficient.

Proactive Quality Assurance

Sustainable Materials and Practices

Comprehensive Mold Care

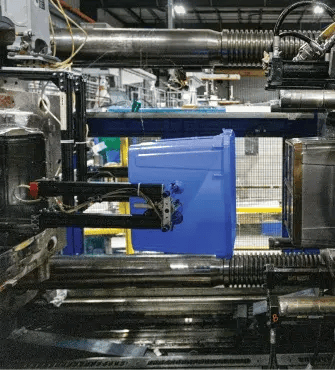

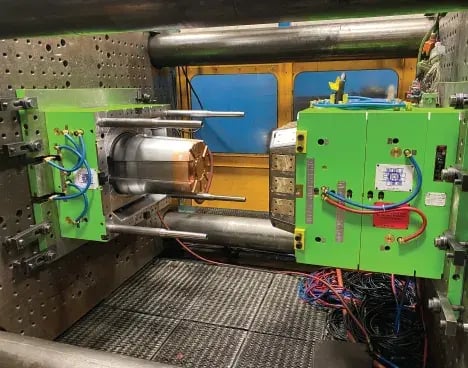

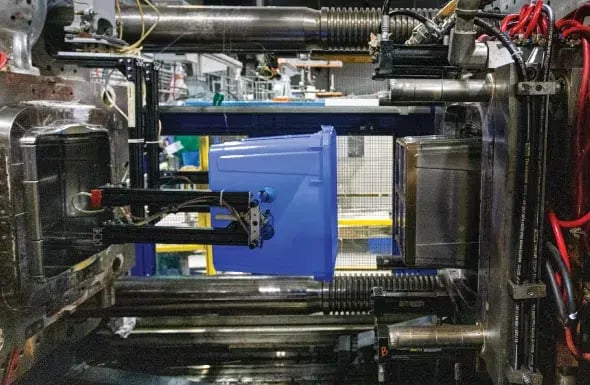

Precision injection moulding capabilities to bring your ideas to life.

Hot Stamping

Add logos, text, or designs directly to your parts with heat-applied precision that lasts. Perfect for branding or product identification.

Sonic Welding

Join plastic components securely with ultrasonic waves. This fast, durable process eliminates adhesives for clean, reliable assembly.

Pad Printing

Transfer detailed images or text onto uneven or curved surfaces. Ideal for branding, labeling, or adding functional markings.

Insert Molding

Embed metal or plastic components into molded parts during production. Create stronger, more functional pieces in one seamless step.

3D Printing and Modeling

Bring designs to life quickly with accurate 3D printing. Perfect for prototypes, concept testing, and refining complex parts.

Your all-in-one partner for injection moulding

Simplify your supply chain with a single partner handling every step of your injection moulding process.

- Save time

- Reduce costs

- Cut lead times

- Boost efficiency

Injection Moulding Capabilities