Injection Moulding for Construction & Plumbing

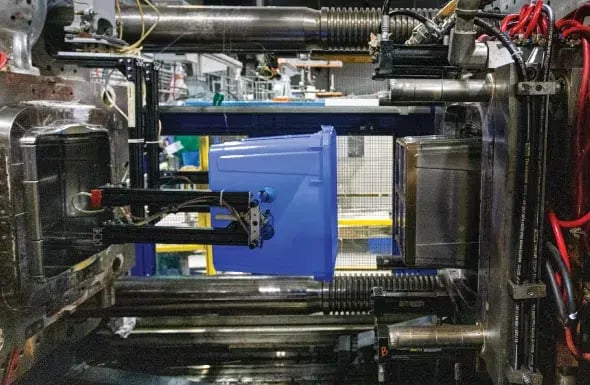

Injection Moulding for Projects That Demand Strength

High-quality, cost-effective injection moulding for plumbing and construction.

In construction and plumbing, parts must perform under pressure—literally and figuratively. Weak or unreliable components can lead to costly delays, compliance issues, or even project failures.

At PenPlast, we understand these stakes. With decades of experience, we produce durable, precision-moulded parts that meet strict industry standards. From plumbing-grade materials like ABS and HDPE to mould designs with interchangeable inserts, we deliver reliable parts built for strength and flexibility.

With our fast lead times, cost-effective processes, and proven quality assurance, you’ll get the parts you need—on time, every time.

Let’s build something great together.

Materials engineered to with stand tough conditions.

Acrylonitrile Butadiene Styrene (ABS)

A strong, lightweight plastic ideal for plumbing systems.

- Durable: Withstands pressure and heavy use.

- Resistant: Handles exposure to chemicals and heat.

- Lightweight: Easy to install and transport.

High-Density Polyethylene (HDPE)

A versatile material for construction and plumbing components.

- Impact Resistant: Protects against cracking under stress.

- Weatherproof: Performs well in extreme temperatures and moisture.

- Eco-Friendly: Available in post-consumer recycled (PCR) grades.

Custom Material Options

applications

Shower Drain Kits.

Elbows & Fittings.

Custom Plumbing Components.

Choose PenPlast. Your partner for precision moulding.

PenPlast is here to help you build stronger, more reliable systems with precision-made injection moulded components.

On-Time Delivery

Flexible Order Volumes

Unmatched Quality Control

End-to-End Support

Sustainable Practices

Your all-in-one partner for injection moulding design

Simplify your supply chain with a single partner handling every step of your injection moulding process.

- Save time

- Reduce costs

- Cut lead times

- Boost efficiency