Agriculture

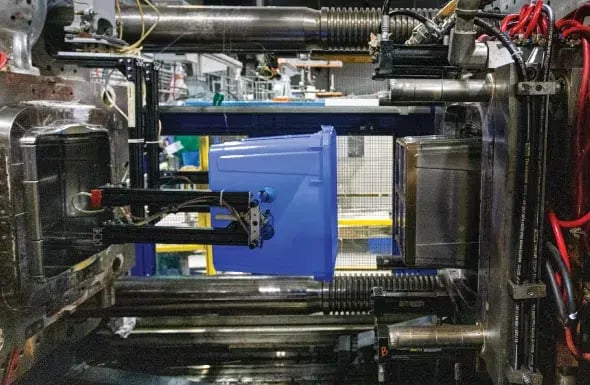

Injection moulding for Agriculture.

Durable, cost-effective injection moulding built for agriculture’s unique demands

In the demanding world of agriculture, every tool, container, and enclosure needs to work as hard as you do. At PenPlast, we specialize in crafting injection moulded products tailored for the agriculture industry, where durability, functionality, and cost-efficiency are non-negotiable.

With over 45 years of experience, we’ve partnered with agriculture professionals across North America to deliver high-quality, commodity-grade HDPE products designed to withstand heavy use and fluctuating demands. Whether it’s grow pots for seedlings or RFID-enabled mushroom lugs, we deliver products that perform season after season.

By choosing PenPlast, you’ll gain more than just a supplier—you’ll get a trusted partner who understands the challenges of seasonality, price sensitivity, and sustainability. Partner with us to deliver products that perform in the toughest conditions.

Let’s Build the Future of Agriculture Together.

Get materials that can handle stress, chemicals, and weather extremes.

High-Density Polyethylene (HDPE)

A workhorse material for agricultural products, HDPE is tough, lightweight, and cost-effective. It resists chemicals, withstands heavy use, and meets food-grade standards.

- Durability: Ideal for heavy-duty applications.

- Chemical Resistance: Performs well with fertilizers and other agricultural substances.

- Eco-Friendly Options: Available in post-consumer recycled (PCR) grades for sustainability.

Polypropylene

Custom Material Options

applications

Grow Pots for Seedlings.

Mushroom Lugs with RFID labels.

Bins and Containers.

Choose PenPlast. Trusted by Agriculture professionals across North America.

At PenPlast, we help agriculture professionals reduce costs, ensure product quality, and manage seasonality with sustainable practices and 45+ years of proven industry experience.

Save Money

Reliable Quality

Handle Seasonal Demands

Eco-Friendly

Proven Expertise

Your all-in-one partner for injection moulding design

Simplify your supply chain with a single partner handling every step of your injection moulding process.

- Save time

- Reduce costs

- Cut lead times

- Boost efficiency